FEBRUARY 2021 UPDATE:

After a year since first receiving my SkyLux, I can no longer recommend Torro Offroad. While the product has been great, I have seen far too many people struggle to receive their orders, struggle to get good customer service, and struggle to receive all the necessary parts when their tents finally arrive. Many people are commenting online that their tent orders take +6 months to arrive depending on when they placed the order. I urge you to do your own research and explore alternative options when searching for your hardshell roof top tent.

After a year since first receiving my SkyLux, I can no longer recommend Torro Offroad. While the product has been great, I have seen far too many people struggle to receive their orders, struggle to get good customer service, and struggle to receive all the necessary parts when their tents finally arrive. Many people are commenting online that their tent orders take +6 months to arrive depending on when they placed the order. I urge you to do your own research and explore alternative options when searching for your hardshell roof top tent.

In the fall of 2019, I was approached by Corey Johnson, founder and owner of Virginia-based Torro Offroad, about testing out their new SkyLux Roof Top Tent (hereinafter referred to as RTT). It’s always a great privilege to be able to try out products for companies, but Corey immediately was adamant about wanting transparency with my thoughts on the tent given the experience we have with our previous COE Vehicle Solutions tent. His enthusiasm for that kind of feedback made the idea of taking the SkyLux off-road and into the elements that much more exciting to me.

The SkyLux is a hard-shell styled tent that unfolds like traditional “soft” tents in the market. What makes this stand out so much compared to our current tent is that it doubles the sleeping space, up from a twin size bed to a king size, integrates an overhang from the elements, comes with a winter insulation kit, and even has integrated LED lights both inside and out for nights at campsites. All in all, a great lineup of features that our current tent (and many other tents, for that matter) simply don’t offer.

The SkyLux is a hard-shell styled tent that unfolds like traditional “soft” tents in the market. What makes this stand out so much compared to our current tent is that it doubles the sleeping space, up from a twin size bed to a king size, integrates an overhang from the elements, comes with a winter insulation kit, and even has integrated LED lights both inside and out for nights at campsites. All in all, a great lineup of features that our current tent (and many other tents, for that matter) simply don’t offer.

Unboxing & Installation

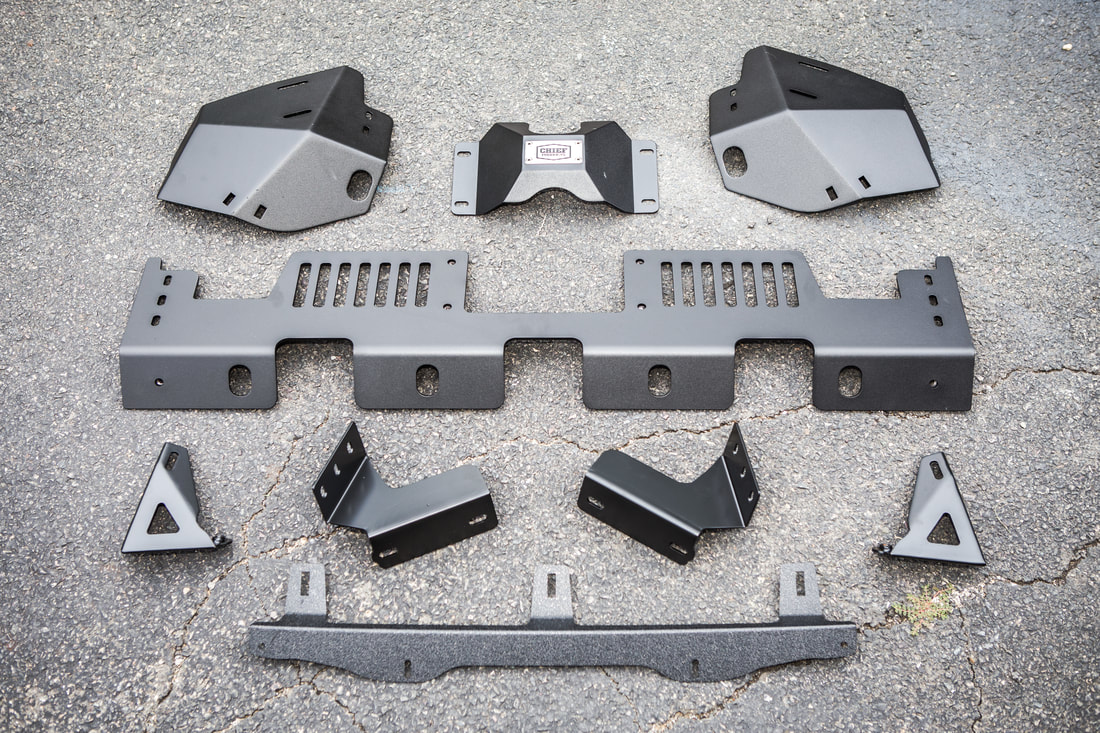

The Torro SkyLux arrived well-packaged in a shipping box alike other items of this size. The delivery company easily moved it around on a pallet and it was dropped inside our garage within a few minutes, safely out of the way of pending inclement weather in the Boston area. My Kershaw knife quickly cut through the packaging material and tape holding everything together, and after moving the large cardboard top piece off and away, I was able to lay my eyes on the sleek silver aluminum frame that comprises the floor of the tent. It came wrapped in a protective plastic which can sometimes be a pain to remove, so I used the tip of my knife’s blade to delicately run down the lengths and edges of the plastic to more easily pull it off. With it removed the underside was completely bare and ready for install, so I flipped the tent over to get a look at it right side up. It weighs in at about 150lbs, which is twenty more than our previous tent, but is comprised of a lot more surface area. I for one would rather know the flooring system is made to support me than to hear it creak every time I move around inside the tent, so the few extra pounds aren’t a huge problem. Chief Product’s new WK2 Roof Rack system is designed to carry over 300lbs dynamic (while in motion) so it’s barely breaking a sweat with the SkyLux up there.

Once the tent was flipped over I made quick work of the six 2” wide Velcro straps and two 1” ribbed plastic retaining straps, and gently lifted the black plastic shell. The two internal pistons immediately took over and raised the clamshell roof to its 60ish-degree angle, exposing both the folded flooring of the tent and the myriad of accessories and hardware that the tent ships with. Included with the SkyLux are the insulation panels for frigid nights, two channel-hung pockets/containers for shoes and the like to be held outside of the tent at night, extra support braces for the gas pistons at super in the event of 40+ MPH winds, and a half dozen metal props for holding the tent’s entryway awning and side windows out when you wish to open them.

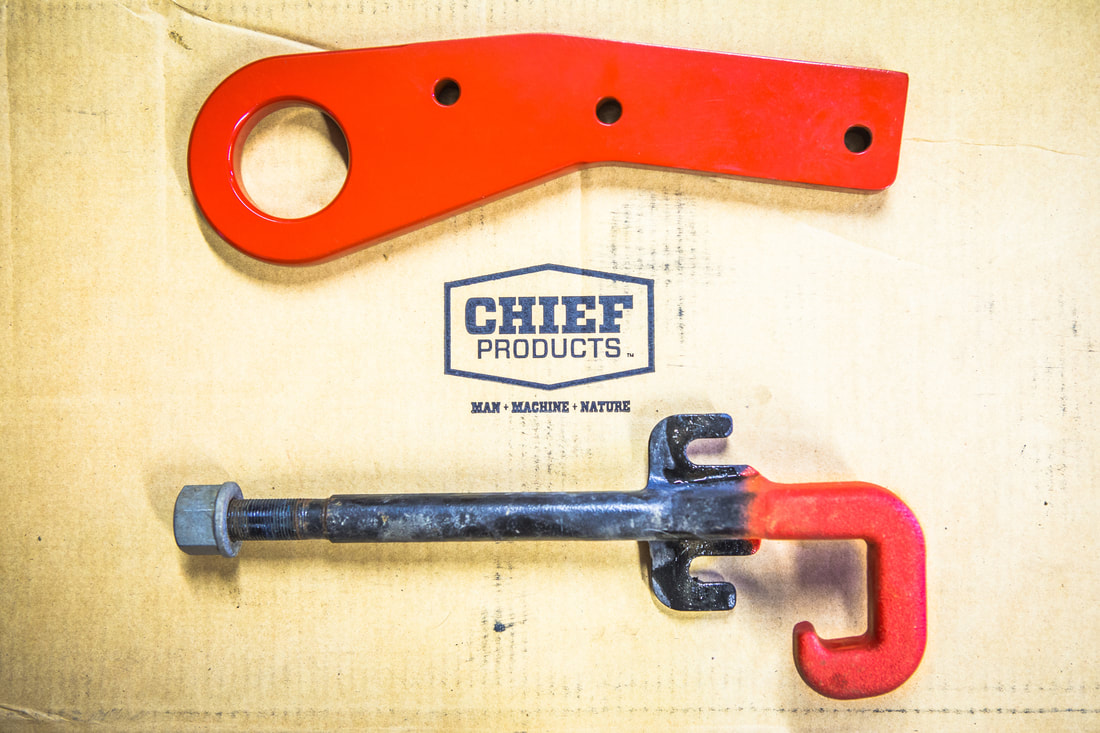

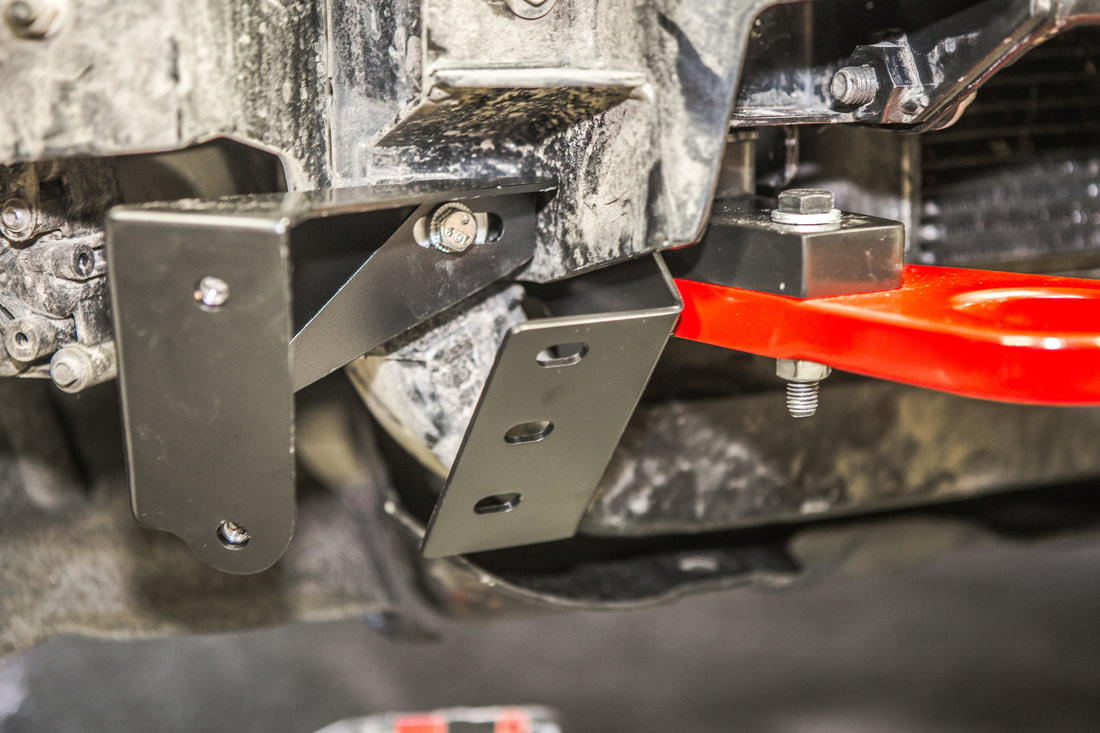

The hardware that’s sent along includes a 13mm ratcheting wrench, eight bolts, four brackets for connecting the tent to your crossbars. In further conversations with the Torro team they’ve told me that the brackets included here (on the left in the photo below) will be replaced with flat bars to cut down on unnecessary tightening on installation. To the right in that same photo are the RTT brackets that Chief Products sells for integrating a tent with their WK2 Roof Rack. The 1/4” steel plates are drilled out perfectly with the Chief crossbar Planks, and allowed the SkyLux to be installed without a hitch.

The hardware that’s sent along includes a 13mm ratcheting wrench, eight bolts, four brackets for connecting the tent to your crossbars. In further conversations with the Torro team they’ve told me that the brackets included here (on the left in the photo below) will be replaced with flat bars to cut down on unnecessary tightening on installation. To the right in that same photo are the RTT brackets that Chief Products sells for integrating a tent with their WK2 Roof Rack. The 1/4” steel plates are drilled out perfectly with the Chief crossbar Planks, and allowed the SkyLux to be installed without a hitch.

Real World Test Run

A mere 24 hours after installation of the SkyLux on the WK2 Trailhawk, I took off for a five day overland trip through Maine’s North Woods with a few friends from our overland group. The temperatures would include single digit nights, 30+ MPH winds, and a thousand miles of travel from our Boston home. Our 1 year old black lab, Delta, came with me on the trip and shared the tent with me each night; not only were we dry in all kinds of weather including rain, hail, and snow, but also warm in our sub-zero sleeping bags. The SkyLux did a great job with ventilation and mitigating build-up of precipitation and only minor frost was exhibited each morning, easy to wipe down with a camp towel every morning.

Having only set the tent up once in our driveway before departure I was quite happy with the 2-3 minute set-up time each night, and nearly identical take-down times each morning. The ladder extended easily and unfolding the tent into its fully opened position was no problem at all for a person to do solo. I mainly utilized the “front door” opening for our ventilation, but did open the side windows on one night for some additional air flow.

In the mornings I moved the sleeping bags to the driver’s side of the tent where the clam-shell hinge resides, which I found made closing the RTT up much easier. From there I’d remove the metal props that keep the doors and windows open, storing the window ones inside an included pouch in the tent, and the door props in the back of the Jeep for easy access at camp each night. This is a habit I’ve had since we first for a roof-top tent, as digging around for these while trying to set up camp isn’t always the most fun activity when all you want is a beer and a campfire.

Once the inside of the tent was set to be stored I collapsed the ladder simultaneously while pushing up and folding the cantilevered aluminum flooring up over onto the main portion of the tent. Think of the closed SkyLux as a tortilla shell folded over in thirds. With the flooring surfaces folded up I then climbed up and collected the fabric shell of the tent, shaking off any snow or ice build-up and tucking it towards the center of the tent before grabbing the nylon strap and pulling down the plastic shell of the tent. The same exceptionally easy Velcro straps were quick to affix, and the plastic locking straps snapped into place despite the snow and ice buildup I faced each morning.

This tent truly seems like it will be a great match for us and our future trips with myself, Dani, and Delta. The space inside, durability, multitude of well thought out accessories, and overall ease of use make it a fantastic product for veteran overlanders/travelers and the newly vehicular adventurous alike. Dani's thrilled about the king-size bed inside, and Delta loves the view from the top of the ladder more than I could ever describe.

I'll circle back after the next few trips and update this with photos and a more long term review, but for now I'll leave you with a link to Torro's website so you can check the SkyLux out for yourself... you might even recognize my Jeep and my wife on their website.

Having only set the tent up once in our driveway before departure I was quite happy with the 2-3 minute set-up time each night, and nearly identical take-down times each morning. The ladder extended easily and unfolding the tent into its fully opened position was no problem at all for a person to do solo. I mainly utilized the “front door” opening for our ventilation, but did open the side windows on one night for some additional air flow.

In the mornings I moved the sleeping bags to the driver’s side of the tent where the clam-shell hinge resides, which I found made closing the RTT up much easier. From there I’d remove the metal props that keep the doors and windows open, storing the window ones inside an included pouch in the tent, and the door props in the back of the Jeep for easy access at camp each night. This is a habit I’ve had since we first for a roof-top tent, as digging around for these while trying to set up camp isn’t always the most fun activity when all you want is a beer and a campfire.

Once the inside of the tent was set to be stored I collapsed the ladder simultaneously while pushing up and folding the cantilevered aluminum flooring up over onto the main portion of the tent. Think of the closed SkyLux as a tortilla shell folded over in thirds. With the flooring surfaces folded up I then climbed up and collected the fabric shell of the tent, shaking off any snow or ice build-up and tucking it towards the center of the tent before grabbing the nylon strap and pulling down the plastic shell of the tent. The same exceptionally easy Velcro straps were quick to affix, and the plastic locking straps snapped into place despite the snow and ice buildup I faced each morning.

This tent truly seems like it will be a great match for us and our future trips with myself, Dani, and Delta. The space inside, durability, multitude of well thought out accessories, and overall ease of use make it a fantastic product for veteran overlanders/travelers and the newly vehicular adventurous alike. Dani's thrilled about the king-size bed inside, and Delta loves the view from the top of the ladder more than I could ever describe.

I'll circle back after the next few trips and update this with photos and a more long term review, but for now I'll leave you with a link to Torro's website so you can check the SkyLux out for yourself... you might even recognize my Jeep and my wife on their website.